Balustrade Wire Kits | Tubular Mount

Self Assembly Wire Balustrade Kits, Tube Mount

Self Assembly Individual Wire Balustrade Kits, Tube Mount

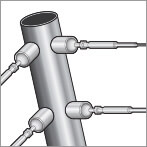

Our complete tube mount balustrade wire kits supply you with everything you require to install a beautiful and refined balustrade infill onto 42.4mm diameter posts.

Priced as individual wire assemblies, produced and engineered in Britain from 316 marine grade stainless steel, giving you a guarantee of durability and quality you can trust.

Each kit will make one single wire only; and are not designed to make multiple lengths out of one kit.

Balustrade Wire Kit - Tube Mount

| Options | Wire Ø (mm) |

Wire Length (metre) |

Tube Mount Sockets | M6 Screws | Tension Fitting | DIY End Fitting | Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|---|---|---|---|

| 1m Balustrade Wire | 4 | 1 | 2 | 2 | 1 | 1 | B4-TB-04-1-A | £38.94 | |

| 2m Balustrade Wire | 4 | 2 | 2 | 2 | 1 | 1 | B4-TB-04-2-A | £41.46 | |

| 3m Balustrade Wire | 4 | 3 | 2 | 2 | 1 | 1 | B4-TB-04-3-A | £43.98 | |

| 5m Balustrade Wire | 4 | 5 | 2 | 2 | 1 | 1 | B4-TB-04-5-A | £46.50 | |

| 7.5m Balustrade Wire | 4 | 7.5 | 2 | 2 | 1 | 1 | B4-TB-04-7-A | £48.42 | |

| 10m Balustrade Wire | 4 | 10 | 2 | 2 | 1 | 1 | B4-TB-04-10-A | £49.74 | |

| 12.5m Balustrade Wire | 4 | 12.5 | 2 | 2 | 1 | 1 | B4-TB-04-12-A | £51.66 |

Tip: To view the product code and full product table on mobile please tilt your device to landscape.

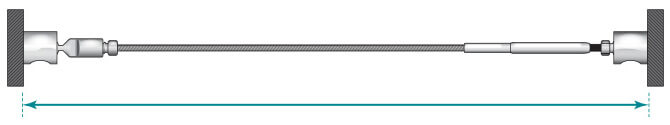

Each assembly consists of:

- 4mm diameter 7x7 stainless steel rope

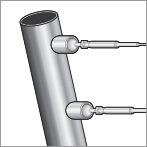

- Two scalloped mounting sockets to fit neatly onto 42.4mm posts

- One attached ball & one removable threaded ball

- One tension adjuster with lock nut

- Supplied complete with all relevant fixings

The Essential Partner

Hand Held Wire Cutters for a neat and tidy cut.

Features

Preserve your view: An example of decking fitted with 4mm wires. The wire gives

a sleek finish and provides an unimpaired view from the deck

Angles:

Ideal solution to allow for shallow angles such as stairs and inclines. The ball and socket design gives articulation of up to 42 degrees.

Installation Advice

Before installation we recommend you consult with your local building control.

Plan your project in advance to ensure you have the correct number of posts, wires and fittings remembering to take into consideration end post and corner post termination clearance and position.

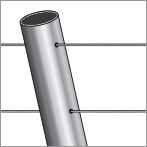

Stainless steel wires should be spaced at a maximum of 100mm apart.

Vertical posts should be spaced at recommended 1.5 metre intervals (up to a maximum of 2 metres apart) to ensure a strong frame.

Measure twice, cut once!

Please be as accurate as possible when measuring and cutting your wire, always double check before cutting.

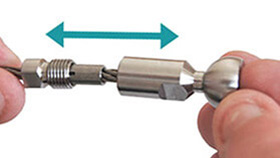

Each cable has an adjustment of plus or minus 20mm.

Cable lengths?

You can run cables up to 12.5 metres!

Pass cables through any intermediate posts to minimise the number of cables you will need!

Need some help?Simply download and print our installation advice sheet for the Tube Mount Balustrade Wire Kit. |

|

DIY Installation Instructions

1. Getting StartedLayout your design onto the relevant surface with a pen or chalk prior to drilling any holes. |

|

2. Drill Pilot HolesYou will need to drill and tap M6 holes into the posts to accept the socket and screw. ('tap' refers to the method of drilling a hole whilst adding an internal thread. A special drill bit is required to achieve this.) |

|

|

We offer a wide range of balustrade tools and accessories to make your installation as smooth as possible. |

|

3. Align SocketThread a M6 screw through the centre hole of your socket and align to the post, with the socket opening pointing downwards (for a neat and tidy finish). |

|

4. Fix SocketUsing a hex head key, tighten the M6 screw until your socket is securely fastened to the post. |

|

5. Prepare Pre-Fixed Ball EndStarting with the pre-fixed tension ball end, screw out the ball end to reveal approximately 20mm of thread, you will need this to apply your final wire tension once installed. |

|

6. Mounting Pre-Fixed Ball EndPlace the pre-fixed tension ball end into the mounting hub. |

|

7. Mark Your Wire For CuttingPull the cable over to the other fixing post and align to the spanner flat of the DIY compression fitting. Mark your wire ready for cutting with either a pen or chalk. Note: The stand off from the mounting hub is 30mm. |

|

8. Cut WireCut your wire to required length, we recommend using a set of good wire rope cutters to give you a neat and tidy cut. Remember - measure twice, cut once! Please be as accurate as possible. Each cable will have an adjustment of plus or minus 20mm. |

|

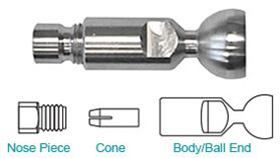

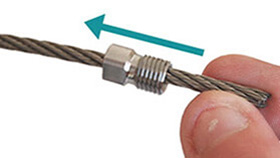

9. DIY Compression FittingYou are now ready to attach the DIY end fitting. The first step is to take apart your DIY compression fitting. |

|

10. Thread Nose Piece onto WireTaking the blank cable end place the nose piece over the stainless steel wire rope (ensuring the thread end is towards the end of your wire). |

|

11. Thread Cone onto WireThread the cone onto the wire and push into the threaded cone chamber. |

|

12. Place Ball End onto WireTake the stainless steel body and push onto the wire, eventually bringing the three component parts together. Turn in opposite directions to thread them together. |

|

13. Secure Ball End FittingUsing a pair of 8mm and 9mm spanners screw the two sections together until tight. |

|

14. Mounting Ball End FittingInsert the DIY ball end into the fixing hole of the hub. Note: if you require more slack in your wire to insert the DIY end simply return to the fixed end ball and unscrew to expand to the required length. |

|

15. Tension WireReturning to the pre-fixed ball end, simply screw in the thread using a 5mm spanner to achieve the desired wire tension. Once you have achieved this lock the nut into place using a 10mm spanner. It is important that the wire rope is not allowed to be twisted. |

|

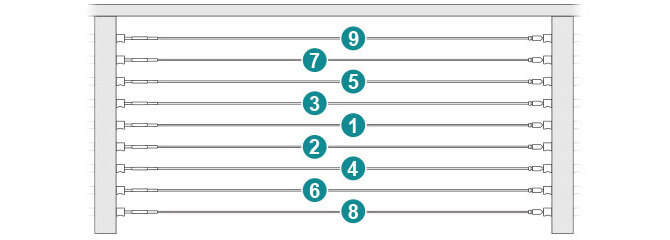

Tensioning Sequence

To tension the balustrade wires, we recommend starting from the centre and working out (see example diagram below). Do not fully tighten individual wires as this will create uneven tension throughout your system, just tighten enough to hold in place. Once all your wires are installed, tighten each wire in turn by slight increments to achieve a solid and fully secure finish.

You may be interested in...

Ready sized and pre-drilled stainless steel posts with welded base plate to accept our wire balustrade hub system.

End Post Pre-drilled for wire balustrade.

Mid Post Pre-drilled for wire balustrade.

Corner Post Pre-drilled for wire balustrade.

Questions & Answers

Reviews